-

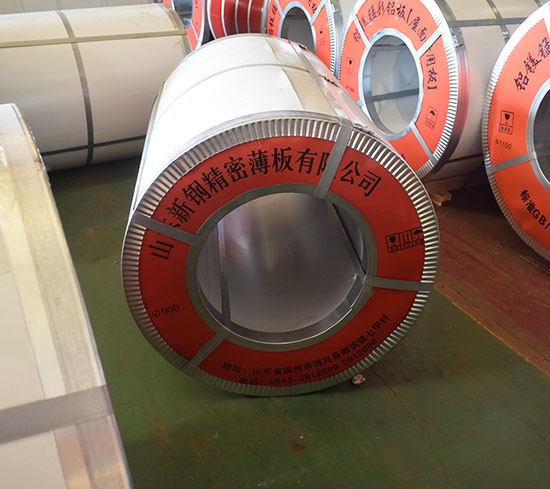

keywords:aluminized zinc Galvanized painted

keywords:aluminized zinc Galvanized painted

Design and cleaning of printing board

2020-11-16 14:43:00

Teach you how to clean up the printed color coating correctly

Most coatings can be used as solid lubricants and meet the lubrication requirements of most forming processes. Some coatings can improve the lubricity of coatings by adjusting the formulation. If the lubrication of the coating is insufficient, the lubricity can be improved by applying oil, waxing and coating strippable protective film. However, it is necessary to pay attention to the simple dirt absorption of wet lubricant and remove it before the device. The peel off protective film shall be removed as soon as possible after the construction.

How to clean up the printed plate

During the process of printing plate cleaning, pay attention to the concentration and temperature of the cleaning solution. The concentration of cleaning solution is too low, and the oil pollution on the surface of the substrate is unclean, which leads to the defects of the post edge coating treatment and then affects the coating quality; if the concentration is too high, zinc and aluminum contained in the galvanized plate are attributed to the amphoteric metal. In the hot alkali solution, the appearance of zinc and aluminum layer simply forms the acid salt, which forms severe corrosion, and then affects the chemical coating effect of the back side.

Chemical cleaning agents generally contain external active agents, and the best temperature of the various surfactants is different (which methods to prevent the fading of printing plates). If the temperature is too high, the stability of the surfactant will decrease, which will decrease the oil removal ability of the cleaning liquid. If the temperature is too low, the saponification reaction speed is slow, and the oil pollution can not be thoroughly eradicated. At the same time, a lot of bubbles will affect the cleaning effect. In addition, the high temperature of the cleaning solution will accelerate the corrosion of zinc and aluminum layer when the solution is added and reduced.

The printing board manufacturer introduces the mechanism, advantages and uses of antibacterial color coating plate to help you purchase when you have the demand in the future.

Antibacterial color coated steel plate, special finish design can kill common bacteria such as Escherichia coli, Staphylococcus aureus and Pseudomonas aeruginosa, and can avoid environmental pollution caused by bacteria and mould propagation and reduce the impact on human health.

Antibacterial mechanism

The key technology of antibacterial color coated steel plate is that there are silver ions in its finish.

The specific mechanism is as follows:

1. interfere with the synthesis of cell wall. The interference of silver ion antibacterial agent on cell wall mainly inhibited the linkage between polysaccharide chain and tetrapeptide, which made the cell wall lose integrity, lost the protective effect on osmotic pressure, and damaged the cell wall and died.

2. damage cell membrane. Cell membrane is an important part of bacterial cell life, such as cell membrane damaged and destroyed, which will lead to bacterial death.

3. inhibit the synthesis of protein. The synthesis of protein changes, stops and kills bacteria.

4. hinder the replication of genetic information, including DNA, RNA synthesis, and DNA template transcription mRNA, etc.

Purpose: it is mainly used in food and drug purification production workshop. Food and drug industry belongs to the special national supervision industry. The sanitation environment of the purification workshop is extremely strict, and unqualified health environment will directly affect the safety of food and drug.

What is printing board adhesive?

1. Appearance: milky white emulsion

2. After a period of application, if the adhesion is reduced, the table surface can be cleaned with clean water or washing powder water for drying, and then the cloth can be directly spread, or the cloth can be coated after one time of drying; the common tableboard glue is researched and produced by the printing board company, and is suitable for all kinds of knitting and woven fabrics used for fixing the function of cloth (cloth) when printing (such as elliptical machine and drawing printing process).

Character: high concentration, not easy to reflect, strong water resistance, strong adhesion, can be repeatedly used without losing its adhesion, not easy to draw. Dq6001b ordinary board adhesive

Characteristics: This product has passed the environmental protection standard certification of SGS printed fabrics (excluding APEO, phthalate and formaldehyde), and belongs to environmental protection type rubber paste.

Most coatings can be used as solid lubricants and meet the lubrication requirements of most forming processes. Some coatings can improve the lubricity of coatings by adjusting the formulation. If the lubrication of the coating is insufficient, the lubricity can be improved by applying oil, waxing and coating strippable protective film. However, it is necessary to pay attention to the simple dirt absorption of wet lubricant and remove it before the device. The peel off protective film shall be removed as soon as possible after the construction.

How to clean up the printed plate

During the process of printing plate cleaning, pay attention to the concentration and temperature of the cleaning solution. The concentration of cleaning solution is too low, and the oil pollution on the surface of the substrate is unclean, which leads to the defects of the post edge coating treatment and then affects the coating quality; if the concentration is too high, zinc and aluminum contained in the galvanized plate are attributed to the amphoteric metal. In the hot alkali solution, the appearance of zinc and aluminum layer simply forms the acid salt, which forms severe corrosion, and then affects the chemical coating effect of the back side.

Chemical cleaning agents generally contain external active agents, and the best temperature of the various surfactants is different (which methods to prevent the fading of printing plates). If the temperature is too high, the stability of the surfactant will decrease, which will decrease the oil removal ability of the cleaning liquid. If the temperature is too low, the saponification reaction speed is slow, and the oil pollution can not be thoroughly eradicated. At the same time, a lot of bubbles will affect the cleaning effect. In addition, the high temperature of the cleaning solution will accelerate the corrosion of zinc and aluminum layer when the solution is added and reduced.

The printing board manufacturer introduces the mechanism, advantages and uses of antibacterial color coating plate to help you purchase when you have the demand in the future.

Antibacterial color coated steel plate, special finish design can kill common bacteria such as Escherichia coli, Staphylococcus aureus and Pseudomonas aeruginosa, and can avoid environmental pollution caused by bacteria and mould propagation and reduce the impact on human health.

Antibacterial mechanism

The key technology of antibacterial color coated steel plate is that there are silver ions in its finish.

The specific mechanism is as follows:

1. interfere with the synthesis of cell wall. The interference of silver ion antibacterial agent on cell wall mainly inhibited the linkage between polysaccharide chain and tetrapeptide, which made the cell wall lose integrity, lost the protective effect on osmotic pressure, and damaged the cell wall and died.

2. damage cell membrane. Cell membrane is an important part of bacterial cell life, such as cell membrane damaged and destroyed, which will lead to bacterial death.

3. inhibit the synthesis of protein. The synthesis of protein changes, stops and kills bacteria.

4. hinder the replication of genetic information, including DNA, RNA synthesis, and DNA template transcription mRNA, etc.

Purpose: it is mainly used in food and drug purification production workshop. Food and drug industry belongs to the special national supervision industry. The sanitation environment of the purification workshop is extremely strict, and unqualified health environment will directly affect the safety of food and drug.

What is printing board adhesive?

1. Appearance: milky white emulsion

2. After a period of application, if the adhesion is reduced, the table surface can be cleaned with clean water or washing powder water for drying, and then the cloth can be directly spread, or the cloth can be coated after one time of drying; the common tableboard glue is researched and produced by the printing board company, and is suitable for all kinds of knitting and woven fabrics used for fixing the function of cloth (cloth) when printing (such as elliptical machine and drawing printing process).

Character: high concentration, not easy to reflect, strong water resistance, strong adhesion, can be repeatedly used without losing its adhesion, not easy to draw. Dq6001b ordinary board adhesive

Characteristics: This product has passed the environmental protection standard certification of SGS printed fabrics (excluding APEO, phthalate and formaldehyde), and belongs to environmental protection type rubber paste.

previous posts:How to make printing board and printing process

next chapter:Teach you how to clean up the color printing board correctly

Product Recommendations

News Recommendation

- How to distinguish color alumi... Six points of attention for pr... How to analyze the adhesion be...

- How to protect the surface of ... Design and cleaning of printin... How to make printing board and...

- Teach you how to clean up the ... How to locate the gauge thickn... How to maintain the surface of...

- Links: cold rolling Galvanized Aluminum zinc plating

- Technical support:zbok

Large iron and steel industry and trade companies

Large iron and steel industry and trade companies

Color coated plate

Color coated plate

Add:Boxing Industrial Park, Shandong Province

Add:Boxing Industrial Park, Shandong Province