-

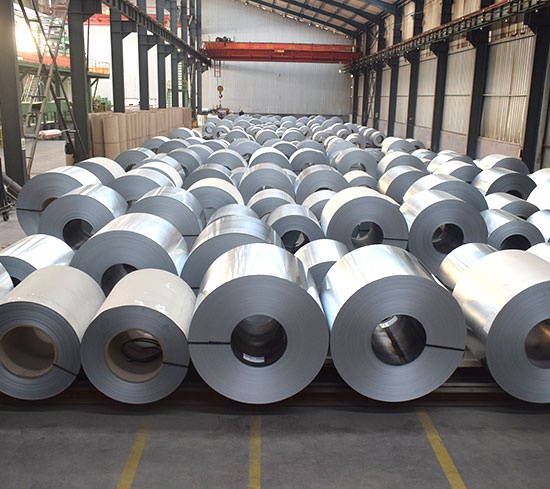

keywords:aluminized zinc Galvanized painted

keywords:aluminized zinc Galvanized painted

How to locate the gauge thickness of printing board

2020-11-15 13:48:00

The standard thickness, length and width recommended by the printing plate and their allowable deviation are listed in relevant product standards.

1. Surface state: due to the different treatment methods in coating process, the surface state of printed board is also different, such as ordinary zinc, fine zinc, flat zinc, no zinc and phosphating surface. The German standard also specifies a surface grade.

2. The printing board shall have good appearance and shall not have defects harmful to the use of the product, such as no plating, holes, cracks, scum, over plating thickness, scratch, chromic acid dirt, white rust, etc. Foreign standards are not very clear about the specific appearance defects. When ordering, some specific defects should be listed in the contract.

3. Standard value of zinc plating amount: zinc plating amount is a widely used and effective method to indicate the thickness of zinc coating on galvanized sheet. The unit of galvanizing amount is g / m2. The regulations of Japanese, American and German standards on the amount of zinc plating of galvanized steel sheet;

4. Dimensions

The recommended standard thickness, length, width and allowable deviation of galvanized sheet are listed in relevant product standards. Refer to the relevant product standards provided in "8" of this section.

5. Appearance

6. Performance index: Generally speaking, only layout, drawing and deep drawing aluminum zinc plate have tensile performance requirements. Among them, the layout of the galvanized sheet requires to have the GeChang conquest point, tensile strength and elongation, etc.; tensile only requires elongation. See the relevant product standards in "8" of this section for specific values;

7. The nominal thickness (increased by 100 times) + code G: refers to common material, P: refers to high oriented material + guaranteed value of iron loss (the iron loss value increased by 100 times when the frequency is 50 Hz and the maximum flux density is 1.7 T).

1. Surface state: due to the different treatment methods in coating process, the surface state of printed board is also different, such as ordinary zinc, fine zinc, flat zinc, no zinc and phosphating surface. The German standard also specifies a surface grade.

2. The printing board shall have good appearance and shall not have defects harmful to the use of the product, such as no plating, holes, cracks, scum, over plating thickness, scratch, chromic acid dirt, white rust, etc. Foreign standards are not very clear about the specific appearance defects. When ordering, some specific defects should be listed in the contract.

3. Standard value of zinc plating amount: zinc plating amount is a widely used and effective method to indicate the thickness of zinc coating on galvanized sheet. The unit of galvanizing amount is g / m2. The regulations of Japanese, American and German standards on the amount of zinc plating of galvanized steel sheet;

4. Dimensions

The recommended standard thickness, length, width and allowable deviation of galvanized sheet are listed in relevant product standards. Refer to the relevant product standards provided in "8" of this section.

5. Appearance

6. Performance index: Generally speaking, only layout, drawing and deep drawing aluminum zinc plate have tensile performance requirements. Among them, the layout of the galvanized sheet requires to have the GeChang conquest point, tensile strength and elongation, etc.; tensile only requires elongation. See the relevant product standards in "8" of this section for specific values;

7. The nominal thickness (increased by 100 times) + code G: refers to common material, P: refers to high oriented material + guaranteed value of iron loss (the iron loss value increased by 100 times when the frequency is 50 Hz and the maximum flux density is 1.7 T).

Product Recommendations

News Recommendation

- Teach you how to clean up the ... Design and cleaning of printin... How to make printing board and...

- How to locate the gauge thickn... How to maintain the surface of... How to analyze the adhesion be...

- How to distinguish color alumi... How to protect the surface of ... Six points of attention for pr...

- Links: cold rolling Galvanized Aluminum zinc plating

- Technical support:zbok

Large iron and steel industry and trade companies

Large iron and steel industry and trade companies

Color coated plate

Color coated plate

Add:Boxing Industrial Park, Shandong Province

Add:Boxing Industrial Park, Shandong Province