-

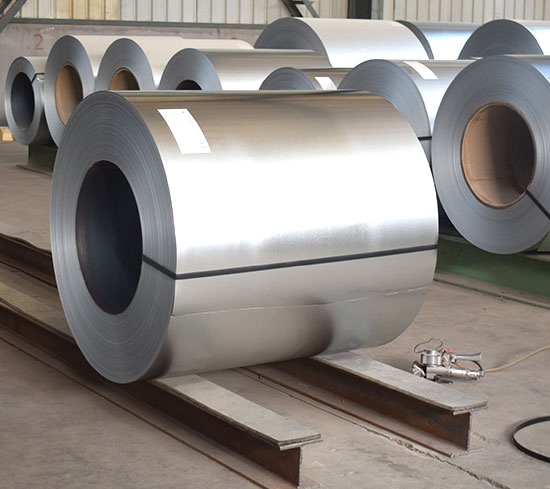

keywords:aluminized zinc Galvanized painted

keywords:aluminized zinc Galvanized painted

-

PROCESS

Large iron and steel industry and trade companies

1.pickling before the inspection and treatment to check whether the tieyi workpiece has the factory galvanized process hole (exhaust, access to the zinc night, hanging), tieyi workpiece surface corrosion degree, surface covering can be removed by hydrochloric acid (such as paint, grease should be used fire, grinding, alkali washing and other methods to remove).

2. Degreasing (alkaline washing) equipped with heating equipment to eliminate grease and paint on the surface of wrought iron workpieces.

3. Wash water to remove alkali water and attachments on the surface of wrought iron workpiece.

4. Remove rust, oxide coating and other surface covering by pickling

5. Check treatment after pickling: Whether the pickling effect is ideal, such as insufficient pickling, pickling again; if the treatment is not thorough before pickling, it shall be treated again after pickling.

6. Wash water to remove acid water and other attachments on the surface of wrought iron workpiece

7. The surface of the workpiece should be cleaned again with plating aid to ensure that the surface will not rust before galvanizing.

8.drying to improve the temperature of the workpiece, avoid iron surface moisture too much, in galvanized explosion.

9. The hot-dip zinc workpiece was immersed in the molten zinc liquid at 440℃-470℃, and after a certain period of time, a zinc-ferroalloy layer and a pure zinc layer were obtained on the surface of the tieart workpiece.

10.passivation provides the surface of the workpiece anti-atmospheric corrosion performance, reduce or extend the appearance of white rust time.

11.cooling to prevent the workpiece cold shrinkage, collective tissue cracking.

12. Clean up the zinc tumor and zinc dust attached to the surface of the coating

13. Inspect the plating layer and the appearance of the workpiece.

- Links: cold rolling Galvanized Aluminum zinc plating

- Technical support:zbok

Large iron and steel industry and trade companies

Large iron and steel industry and trade companies

Color coated plate

Color coated plate

Add:Boxing Industrial Park, Shandong Province

Add:Boxing Industrial Park, Shandong Province